How to Open a Pepsi Vending Machine Without a Key

Tom has 17 years of experience as a commercial locksmith and over 20 years in door hardware distribution.

Learn how a key machine operates and how it accurately cuts keys

Key Cutting Machines

Ah, the sound of brass being cut by a carbide steel rotating blade. If you've ever gotten a key cut, you know the sound is just not pleasant. However, it is unique. Nothing sounds quite like it. And, if you listen to it long enough with no ear protection, then that's exactly what you'll hear: nothing.

Yet, it is fascinating, isn't it? This screaming little piece of equipment. A closer look reveals that it is really a marvel of mechanical engineering.

Kaba Ilco model 045 HD Key Duplicating Machine

Kaba Ilco

Above is a picture from a brochure advertising key duplicating machines made by Kaba Ilco. This particular key machine is probably not much different than the first key machine ever made. It is certainly safer to use, but its operating principles are the same.

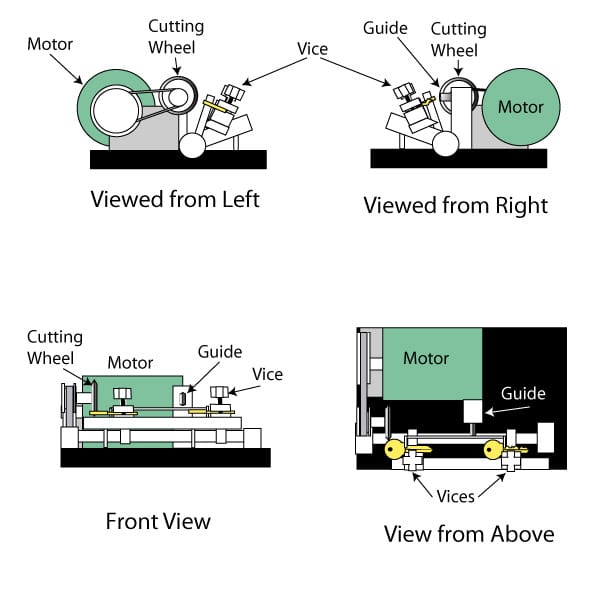

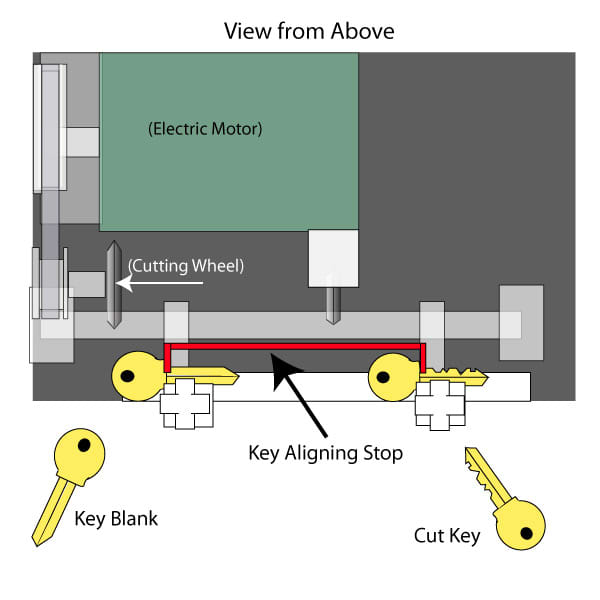

Below I have designed my own key machine with no shielding to protect the user from losing a finger or getting a brass filing in the eye. I did not design it for any other purpose than to illustrate how a key machine works.

NOTE: This article does not review or recommend models of key machines or discuss various types of key machines, but simply discusses how a traditional key machine with a cutting wheel works.

Illustration by Tom Rubenoff

Key Blank vs. Original Key

artwork by Tom Rubenoff

Sum of Its Parts

The above illustration is of a key machine designed to cut keys for everyday pin tumbler locks. Like all such key machines it has:

- A means of turning the cutting wheel (in this case an electric motor)

- A cutting wheel

- A vice to hold the key blank

- A vice to hold the original key

- A guide

- A key alignment device

NOTE: The following describes how a key machine is used. Do not use this paragraph for directions on how to use a key machine. Before you use a key machine, consult the manufacturer's instructions and read all safety precautions carefully.

To use the key machine, an original key is inserted into the vice that is near the guide and a key blank is inserted in the vice near the cutting wheel. Using the alignment device, usually two bars that are connected to ensure they always remain the same distance apart, the keys are horizontally aligned in the vices to be in precisely the same place in relation to the cutting wheel and guide. The motor is energized and spins the cutting wheel. As the user traces the guide along the cuts of the original key, the key blank is dragged along the cutting wheel, duplicating the cuts on the original. When all the cuts have been cleanly made the process is complete.

After the key is cut, burrs are removed usually by buffing the key with a rotary wire brush either mounted on the key machine itself or on a grinding machine.

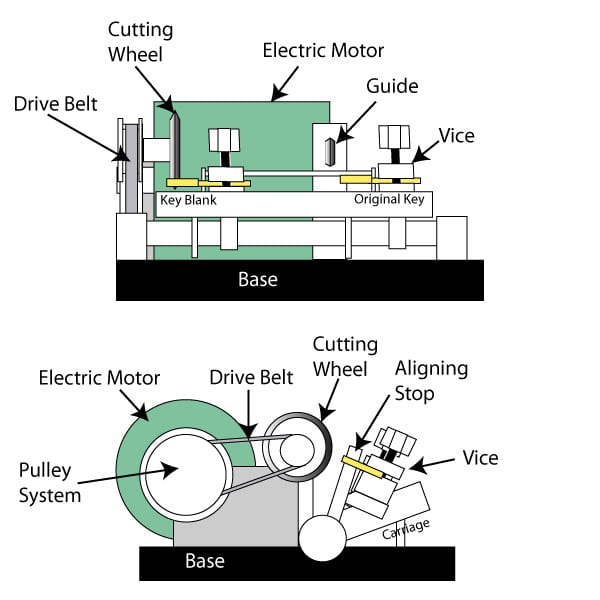

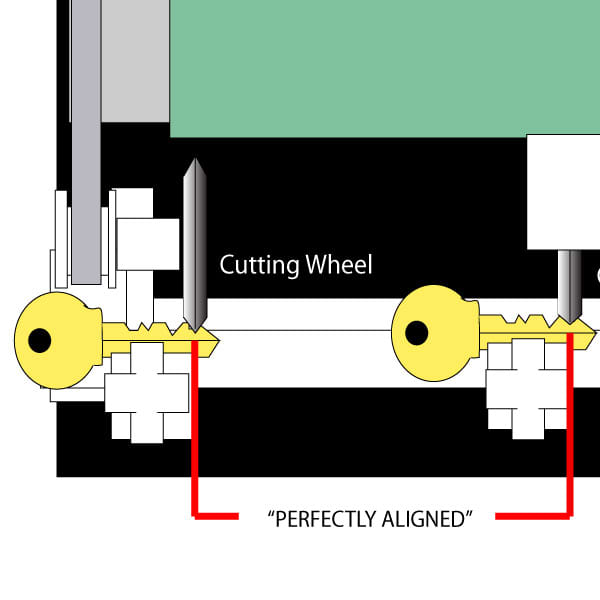

Below is another illustration of the key machine I designed just now, a little closer up.

Illustration by Tom Rubenoff

Illustration by Tom Rubenoff

Illustration by Tom Rubenoff

Key Alignment

The above illustration shows the key blank and original key inserted in the vices of the key machine and the alignment device in place, shown in red.

Read More From Dengarden

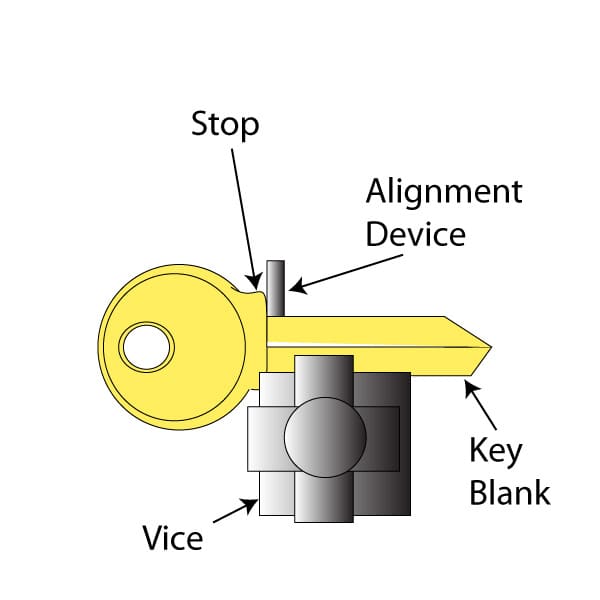

A key factor (if you'll pardon the expression) in cutting accurate keys is alignment of the key blank in relation to the original key. The cutting wheel is in a fixed position, but the guide can be adjusted in or out to compensate for the gradually wearing away of the cutting wheel during the course of duplicating thousands of keys. Keys and key blanks are fully inserted into the vices so that their backs are against a ledge inside the jaw of each vice, therefore their relative distance from the cutting wheel is the same.

Side-to-side alignment is achieved through the use of an alignment device - usually milled from a single piece of steel with two arms. The key and blank are slide sideways in their vices until both of their stops rest against their arm of the alignment device. Therefore the key and blank are aligned so that they are precisely the same distance apart as the cutting wheel and guide.

Above, on the right side, is a close up of a key blank inserted in the vice with the stop of the key resting against the alignment device.

Below is an illustration showing the relative position of the almost completed duplicate, the original key, the cutting wheel and the guide during the key duplication process.

Illustration by Tom Rubenoff

"Perfect"

The more precisely a key can be duplicated, the better the duplicate will work in the lock. Variables that affect precision in the key duplication process using a machine with a cutting wheel are:

- Key blank quality

- State of the original key

- State of the cutting wheel

- Adjustment of the guide

- Skill of the operator

Key blanks are made by many companies in many countries. Most countries use the metric system whereas other countries use fractions of an inch. A discrepancy of 1/1000 of an inch can affect key performance; a difference of 3/1000 of an inch can mean that a duplicate will probably not work in the lock. High quality blanks are milled to precise specifications that match the manufacturer's original. The best blanks are usually made by the manufacturers of the locks that the blanks are made to fit.

Keys and locks grow old together. Insertion of a key produces friction, and friction produces wear. Pin tumblers and keys are usually made of a softer metal such as brass. As your key gets old you can observe that the peaks and valleys of the cuts are no longer sharp, but have become rounded. The same thing has probably happened to the pin tumblers inside your lock. In addition, all sides of the key wear away, making the original gradually shrink over time. All of these factors affect the ability of the key machine to duplicate the original accurately.

Key machine cutting wheels are made of carbide steel—much, much harder than the brass and nickel-silver key blanks they cut. That's why a cutting wheel can be used to cut thousands of keys and they will all be within close enough tolerances to work properly—until one day they are not. Cutting wheels get dull over time just like any other cutting tool, and when they do, the critical alignment necessary to duplicate keys is compromised.

For a while one can compensate for cutting wheel that is becoming worn by adjusting the guide. As the cutting wheel nears the end of its life it becomes smaller. Therefore the guide can be moved away from the vices slightly to compensate; however, as the wheel wears the cutting edge also becomes wider. No adjustment can compensate for that, so at that point the cutting wheel must be replaced.

Key machine operator skill varies widely. Some have no clue what they are doing at all, having had only some rudimentary instruction that has left out the important details of why copies of keys work and why they do not. Others are highly trained technicians who know absolutely everything about duplicating keys. It's kind of like Forrest Gump's box of chocolates: You never know who you are going to get.

Tips for Getting Accurate Key Duplicates

Well, for starters, go to a place that guarantees their keys will work. At least then if it doesn't work you can return it and have them try again or you can get your money back.

Try to get the original original. Look at your lock and find the name of the manufacturer. The name of the manufacturer will usually appear on the original key. If your key has the name of key blank manufacturer rather than the name of a lock manufacturer, you do not have an original key, but only a copy. Copies of copies rarely work as well as a copy of a genuine original key.

Ask your key duplicator to use manufacturer's original key blanks. Many key duplicators can provide manufacturer's original blanks. When you start out with the manufacturer's original blank, you have the best chance of getting the most accurately cut key.

Choose a key duplicator who has an array of key machines. If a key machine operator operates many key machines s/he must have an understanding of the key cutting process. A person who understands the process will most likely cut a better key.

Replace worn locks when they first start to give you trouble. If you are getting keys cut by a competant key cutter on good equipment using manufacturer's original blanks and you are consistently getting bad results, chances are it is either your lock, your key, or both that are the issue. It very well could be a signal that it is time for you to replace your lock and get new keys.

This article is accurate and true to the best of the author's knowledge. Content is for informational or entertainment purposes only and does not substitute for personal counsel or professional advice in business, financial, legal, or technical matters.

© 2013 Tom rubenoff

Tom rubenoff (author) from United States on August 31, 2013:

Thank you, Epbooks!

Elizabeth Parker from Las Vegas, NV on August 31, 2013:

This was an excellent, well-written and informative hub. I won't be buying a key machine at all, but for those who have one, these instructions are perfect!

How to Open a Pepsi Vending Machine Without a Key

Source: https://dengarden.com/home-improvement/How-Do-Key-Machines-Work

0 Response to "How to Open a Pepsi Vending Machine Without a Key"

Post a Comment